Data analytics for supply chain management

Take supplier and inventory management to the next level with advanced BI and analytics software.

Effectively manage your inventory

- Monitor the status of goods, shipments, and inventory levels across your supply chain.

- Analyze patterns to detect issues in how your inventory is being handled.

- Get advanced reporting on demand variability, supplier performance, and lead times.

Plan with more accuracy

- Aggregate your data and visualize it on interactive dashboards.

- Get real-time insights into key performance metrics, enabling quick response to issues.

- Uncover patterns among different sources, and setup automatic alerts.

Increase efficiency to reduce costs

- Optimize warehousing and transportation to achieve cost savings.

- Align supply with demand, minimize waste, and reduce carriage costs.

Dive deep into our success stories

Examples of supply chain dashboards

Check out how supply chain teams are using dashboards.

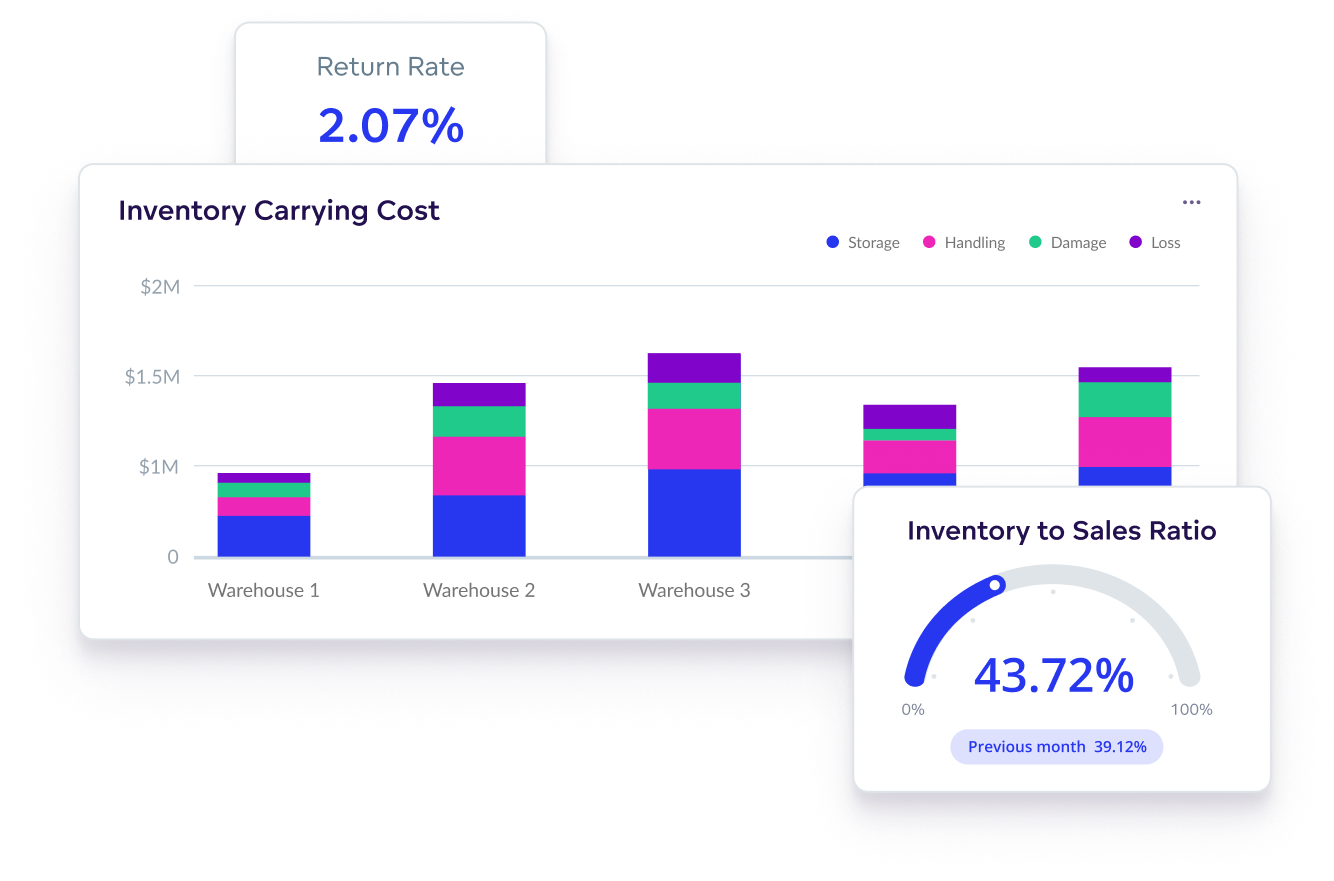

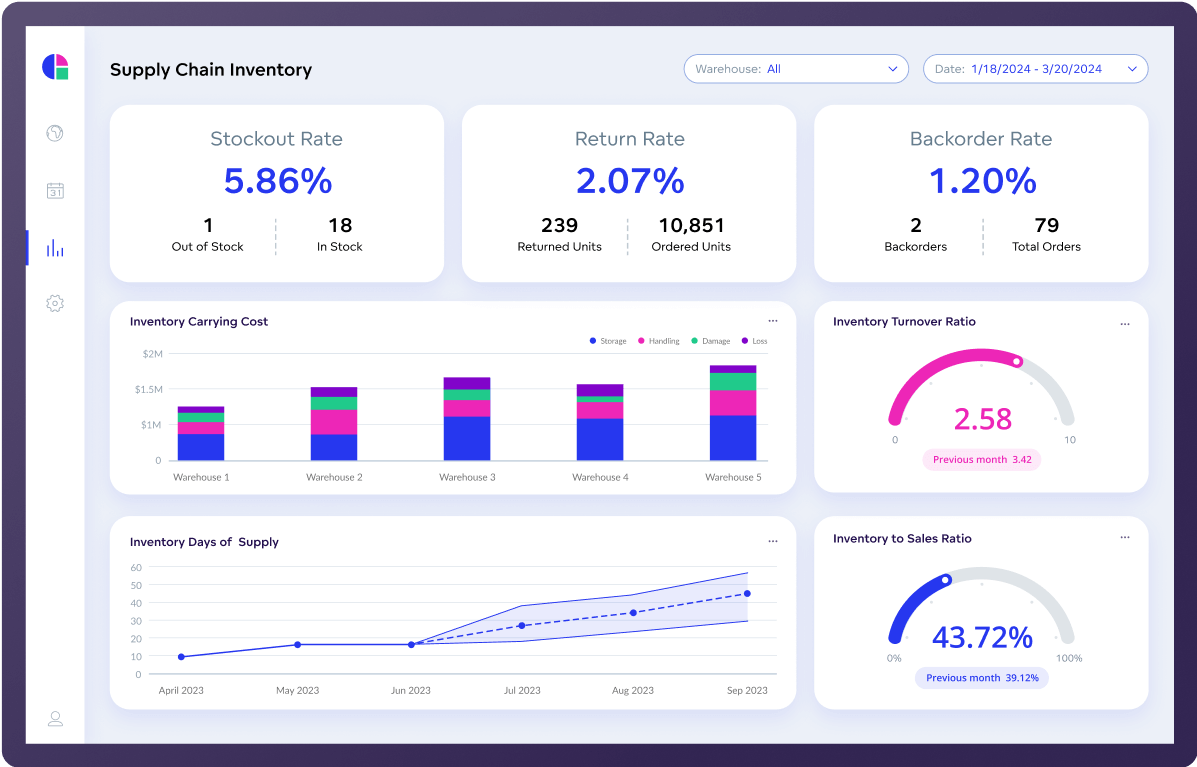

Real-time overview of inventory

Management can visualizes key metrics, such as stockout rate, returns, and backorders, ensuring they know what’s in their warehouse at all times.

- Bold visualizations for fast inventory insights.

- Drillable charts for warehouse managers and specialists.

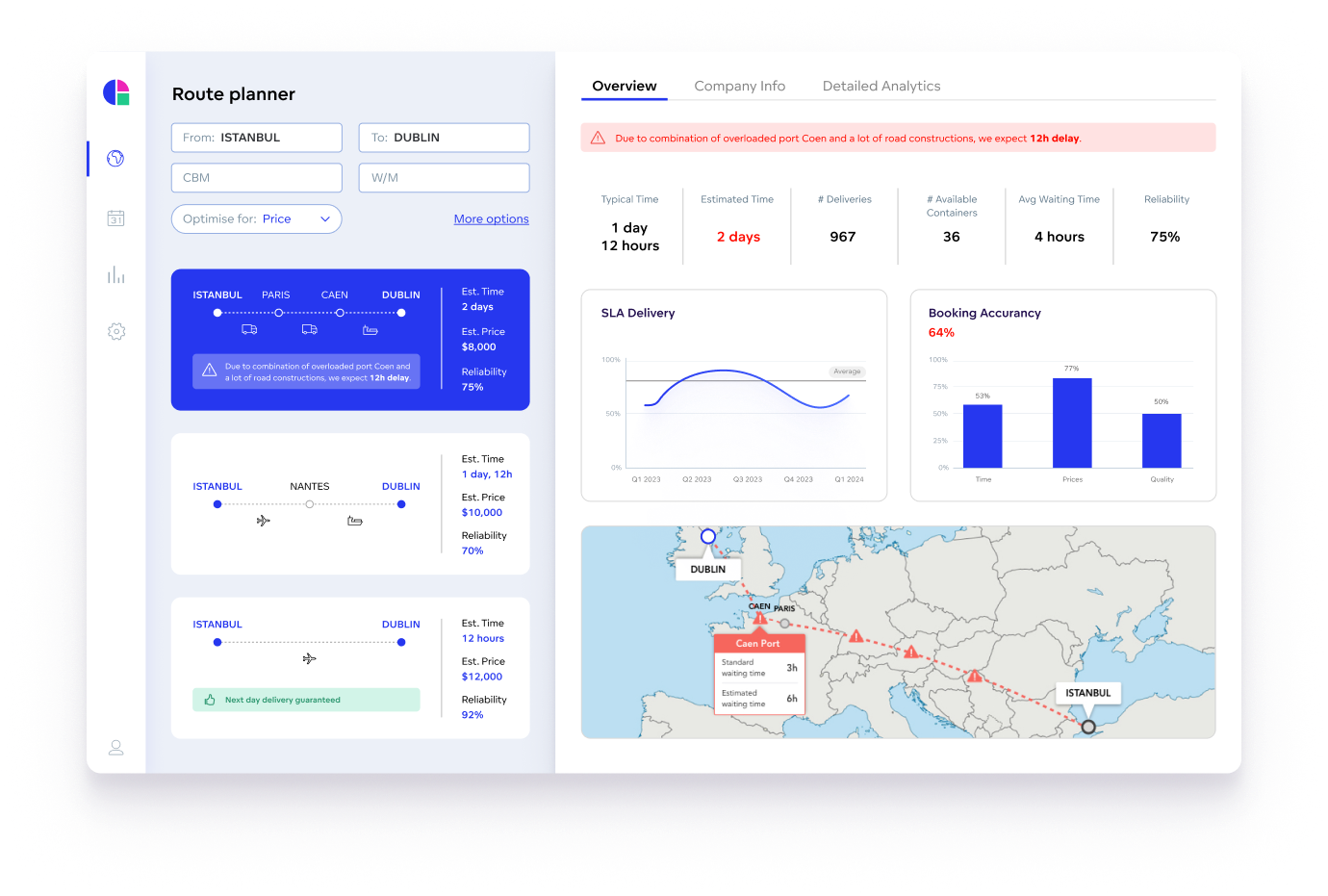

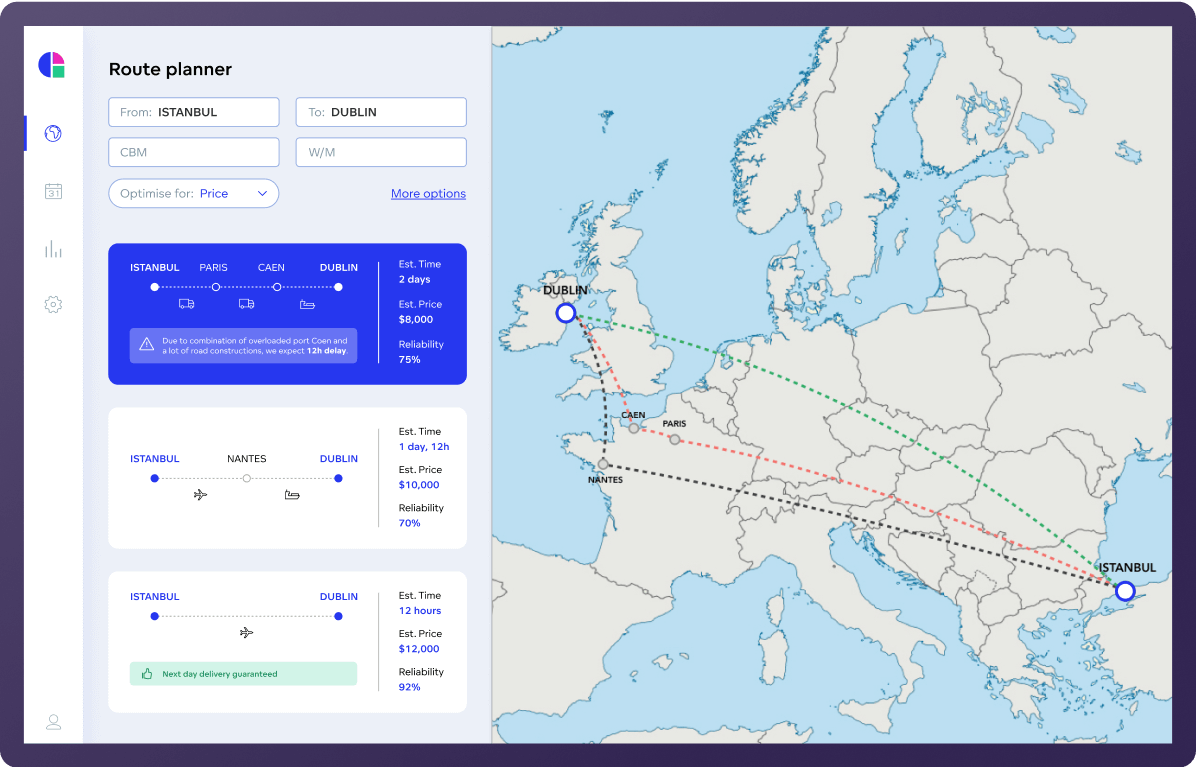

Birdseye view of delivery operations

See fleet delivery status by destination and obtain at-a-glance knowledge of loading time and weight — with automatic alerts for anomalies or delays.

- Easily embeds into current software set ups.

- Pre-configured, automated alerts to flag delays.

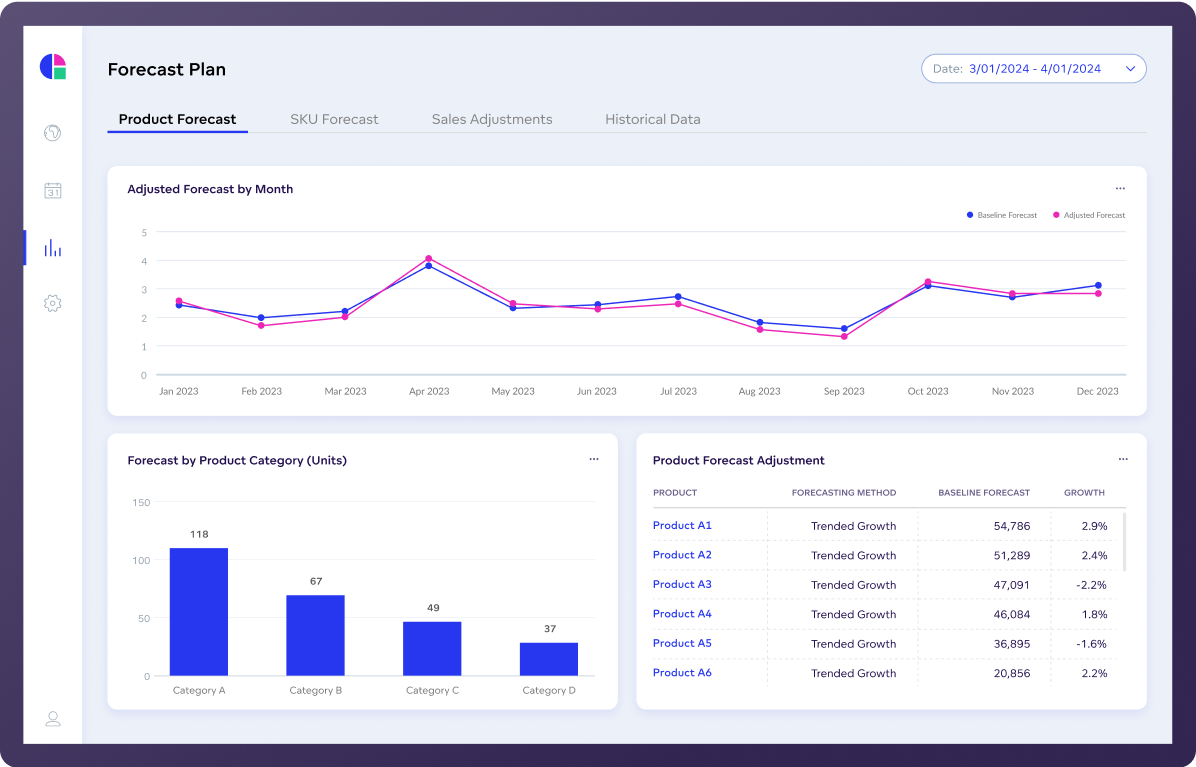

Forecasting for sales plan optimization

Uses historical data and AI-fueled forecasting to predict supply chain demands for the upcoming period.

- Advanced analytics features for fast financial forecasting.

- Customizable visualizations display user-specific metrics.

Discuss your use case with us

See how GoodData can help with your analytics goals.

Why choose our analytics platform?

Reasons why companies love our analytics platform include:

Smoothly implement in your ecosystem

Deploy in GoodData Cloud

GoodData Cloud is a SaaS product operated and maintained by us. Customers receive continuous code updates and it can be deployed in AWS, Azure, and multi-region.

Deploy Self-hosted

Self-hosted uses the same codebase as GoodData Cloud and is ideal for users needing enhanced security, governance, or control for data residency or regulatory compliance.

Integration

Open APIs and declarative SDKs — connect to code repositories and 3rd-party apps, embed anywhere.

Security and governance

Trusted analytics — certifications, inherited permissions, and cascading content changes for easy admin.

Accessibility

Accessible analytics — ensuring compliance and delivering inclusive experiences.

A trusted platform, loved by users

Common supply chain analytics questions

The key benefits of a supply chain analytics tool include:

- Improved demand forecasting: Analytics tools use historical data and predictive models to accurately forecast demand. This allows companies to be more responsive to market trends and customer demands, reducing the risk of stock running out or excess inventory.

- Better supply chain visibility: Supply chain analytics tools allow businesses to monitor the status of goods, shipments, and inventory levels across the supply chain. This improved visibility helps identify potential disruptions early to mitigate risks.

- Improved supplier management: Analytics tools evaluate supplier performance, identifying areas for improvement and strengthening supplier relationships. Companies can then better assess and manage supplier-related risks, such as delays or quality issues.

- Strategic decision-making: Data-driven insights lead to more informed supply chain decisions. They also allow for scenario planning and simulation, helping companies evaluate the potential impact of strategic changes or disruptions.

- Improved customer satisfaction: Accurate demand forecasting and inventory management lead to higher service levels as products can be made available when and where customers want them. Analytics can also identify customer preferences and trends, enabling companies to tailor product offerings and services to meet specific customer needs.

- Adaptability: Advanced analytics tools help businesses quickly adapt to market changes, customer preferences, or supply chain disruptions. Companies with agile supply chains are better positioned to respond to challenges and take opportunities.

- Sustainability improvements: Analytics can identify opportunities to optimize resource use, reduce energy consumption, and minimize waste to support sustainability goals and comply with regulatory requirements.

There are several things to consider when deciding on an analytics tool. Below are some steps you can take to make the right choice for your use case:

- Define your requirements: Start by clearly defining your analytics requirements. Identify the specific use cases and key performance indicators (KPIs) you want the BI tool to support.

- Evaluate features and functionality: Look for BI tools that offer features and functionality tailored to supply chain analytics. Key features to consider include data visualization capabilities, ad-hoc reporting, predictive analytics, drill-down capabilities, and rich integration options.

- Scalability and flexibility: Choose a BI tool that can scale with your evolving analytics requirements. Consider whether the tool supports flexible data integration from multiple sources.

- Ease of Use: Choose a BI tool that is user-friendly and intuitive. This will allow supply chain professionals with varying levels of technical expertise to easily access and analyze supply chain data. Look for features such as drag-and-drop interfaces, customizable dashboards, and self-service analytics capabilities.

- Vendor reputation and support: Read customer reviews, case studies, and analyst reports to assess the vendor's reliability, customer satisfaction, and level of support.

- Cost considerations: Evaluate the total cost of ownership (TCO) of the BI tool, including licensing fees, implementation costs, training expenses, and ongoing support and maintenance costs. Choose a BI tool that offers transparent pricing and aligns with your budget constraints.

Here’s how you can leverage AI and advanced analytics in your supply chain:

- Implement predictive analytics for demand forecasting: Use AI models to analyze historical sales data, market trends, consumer behavior, and external factors like economic indicators to predict future demand. You can even adjust inventory levels and production schedules in real-time to match the forecasted demand, reducing over- and understocking.

- Optimize inventory management: Deploy machine learning algorithms to analyze patterns and variability in demand, supplier performance, and lead times to optimize inventory levels. You can also implement tools for automated reordering and dynamic pricing strategies based on predicted demand and stock levels.

- Enhance supply chain visibility: Adopt real-time tracking solutions that use IoT devices and sensors to monitor the location and condition of goods in transit. Use dashboards and analytics platforms to aggregate and visualize data, providing insights into performance metrics and enabling quick response to issues.

- Improve logistics and transportation: Apply advanced analytics to optimize route planning, considering factors such as traffic conditions, weather, and delivery windows.

- Drive sustainability initiatives: Leverage analytics to monitor and manage the environmental impact of supply chain operations, including carbon emissions and resource use. Use AI-driven insights to identify opportunities for using sustainable materials, optimizing routes for fuel efficiency, and reducing waste.

Advanced supply chain analytics leverages big data, machine learning, predictive analytics, and other advanced technologies to provide deeper insights and more accurate forecasting. Key features include:

- Predictive analytics: Uses historical data and machine learning algorithms to predict future trends and outcomes.

- Real-time visibility: Provides up-to-the-minute insights into supply chain operations, allowing companies to monitor the status of goods in transit, inventory levels, and production schedules in real-time.

- Risk management: Advanced analytics can identify and assess risks throughout the supply chain by analyzing data from various sources, including market trends, geopolitical events, and natural disasters.

- Integration and collaboration: Facilitates the integration of data from various sources within the supply chain, including suppliers, manufacturers, distributors, and retailers. This leads to improved collaboration among all stakeholders, ensuring a more coordinated and efficient supply chain.

- Cost reduction and efficiency: By optimizing routing, inventory levels, and production schedules, advanced analytics can help reduce operational costs, minimize waste, and improve overall efficiency.

- Sustainability and compliance: Helps companies monitor and manage their environmental impact and ensure compliance with regulations by analyzing data related to carbon footprint, waste management, and the use of sustainable materials.

Try GoodData yourself

See how GoodData can help with your analytics goals